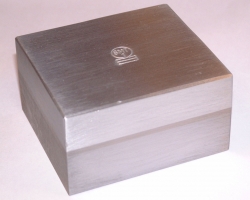

Cladding Materials

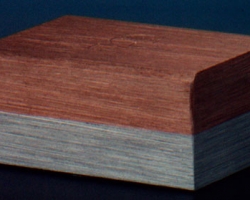

The base metals are typicaly carbon steel, stainless steel, alloy steel, copper and aluminium.

The cladding metals are mainly stainless steel, duplex steel, titanium, aluminium, copper, copper alloys, nickel, nickel alloys, tantalum, and zirconium.

|

Base Metals

Product Type

Sizes / Capacity

|

Cladding Metals

|

Advantages of Explosion Cladding under Vacuum

- Short delivery time: complete production under one roof

- Excellent process control (no weather influences and circumstances)

-

Because of vacuum, less explosives are required.

-

As results:

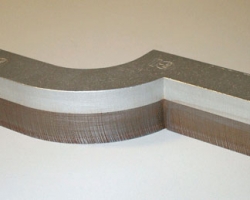

- Less deformation

- Hardness of the clad plate slightly increase

-

As results:

- Costs saving: thin layer of expensive material cladded on a thicker layer of cheap material.

- Metal combinations possible which are conventional impossible to weld.

- Original metal properties maintain.

- Joint/bond stronger than the weakest material.

- Oxide free atomic bond

- Electrical resistance of anode / cathode blocks nil.

- Required clad layer thickness in 1 step realized

- Smooth surface after cladding

- Intermediate quality control not necessary