Explosive Cladding

The impact produces sufficient energy to cause the colliding metal surfaces to flow hydro dynamically when they intimately contact one another in order to promote solid-state bonding. The metal surfaces are compressed together under high pressure from the explosion, and an atomistic bonding between the dissimilar metals will be accomplished.

Explosive cladding is a cold ‘pressure weld process (at room temperature)’. It is a method to weld metals that cannot be welded by conventional processes, such as titanium-steel, aluminium-steel and aluminium-copper. It can also be used to weld compatible metals, such as stainless steels and nickel alloys to steel. The cladding metals are typically stainless steel, duplex steel, titanium, aluminium, copper, copper alloys, nickel, nickel alloys, tantalum, and zirconium.

Fabrication Process

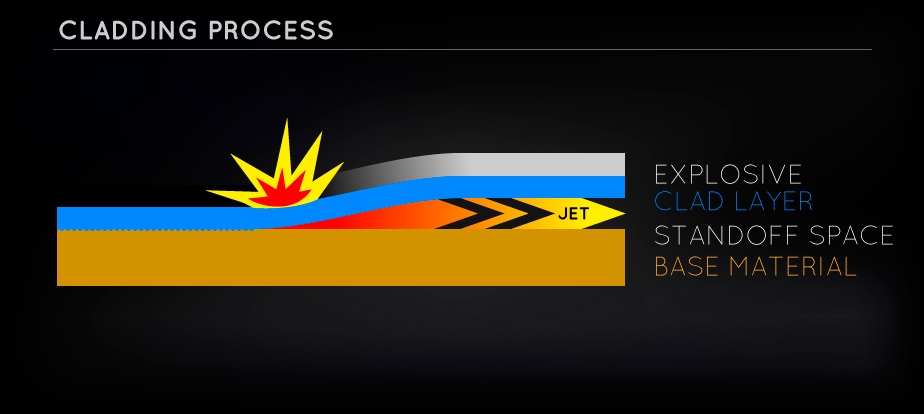

The cladding process is started with the preparation (Grinding and Cleaning) of the surface of both base material and clad material. The clad material is placed on top of the base material and between the two materials we place spacers to keep an appropriate ‘stand-off’. The assembly of the materials is accomplished in accordance with the clad set-up parameters (stand-off gap, quantity of explosives, surface protection, ignition point). The clad assembly will be put in the vacuum chamber, on top of a prepared sand bed. The powder explosives will be applied on the clad surface together with the booster charge. After placing the electrical detonator, the vacuum chamber will be closed and the evacuation of the air will start.

When the under pressure reach the required value, the detonation of the explosive charge will take place by ignition the detonator at the control room.

The cladded plates will be further prepared for finishing: Visual check, flattening, US examination, DT/NDT and packed for transport.